Vertical Machines

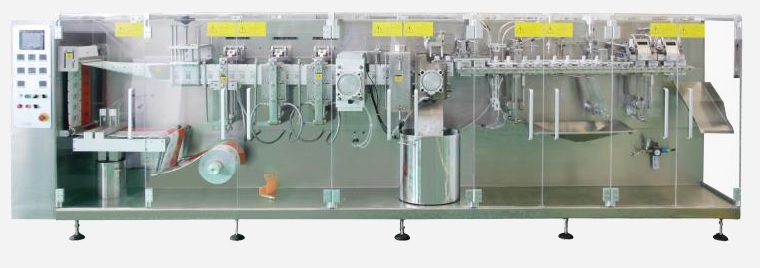

Multi-Lane Stick VFFS Packing Machine MLP-480 Series

| Standard Features: | |

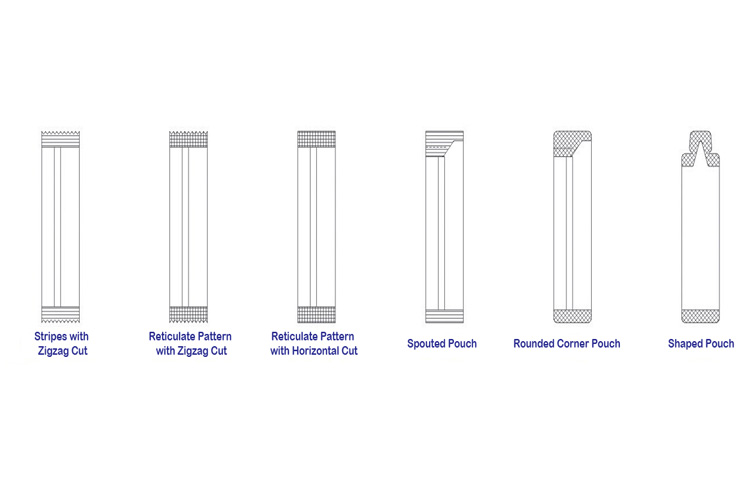

| 1. | The machine can automatically complete multi-lane products measuring, feeding, filling and bag forming, date code printing, bag sealing and cutting. And hole punching as option. |

| 2. | Motor driven heat seal film pulling system. |

| 3. | High sensitive fiber optic photo sensor can automatically trace color mark accurately. |

| 4. | PLC control system combined with touch screen, can easily set and change the packing parameters. Daily production output and self-diagnostic machine error can be viewed directly from the screen. |

| 5. | PID temperature controller monitors heat sealing temperature within ±1°C |

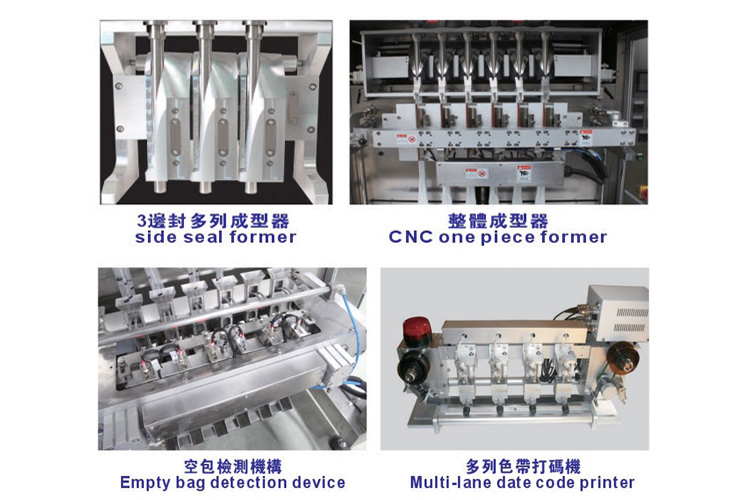

| Optional Parts for Main Machine: | |

| 1. | Date Code Printer |

| 2. | Straight Line Cut with easy tear |

| 3. | Hole punching device |

| 4. | Fix number bag cutting device |

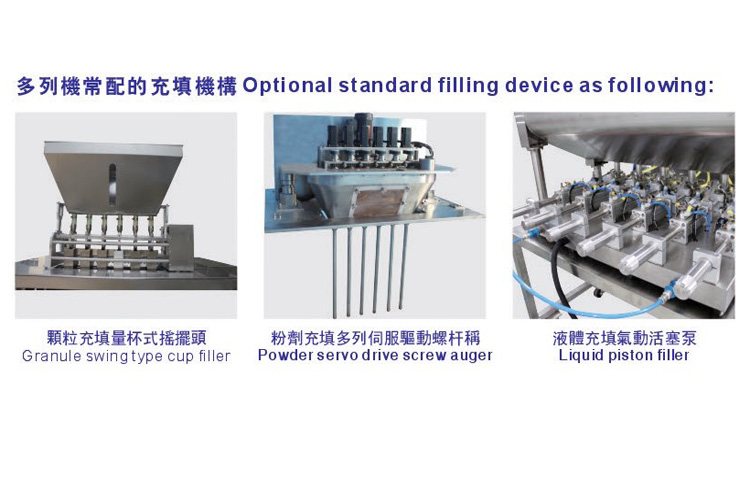

| Optional Dosing Device: | |

| 1. | Auger screw Filler (for powder) |

| 2. | Volumetric Cup Filler (for granule) |

| 3. | Electrical Gear Pump (for liquid) |

| 4. | Piston Pump (for liquid or cream) |

| Model No. | MLP-480-04 | MLP-480-06 | MLP-480-08 |

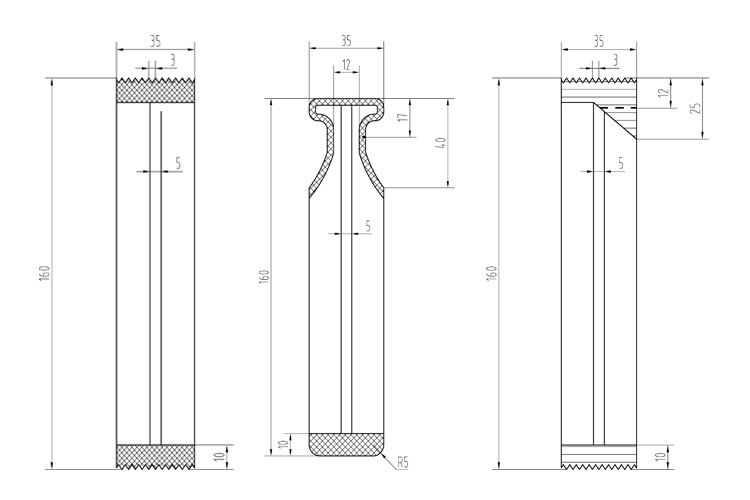

| Bag Length (mm) | 70-200 | 70-200 | 70-200 |

| Bag Width (mm) | 16-50 | 16-35 | 16-25 |

| Film Width(mm) | Max. 480 | Max. 480 | Max. 480 |

| Lanes No. | 4 | 6 | 8 |

| Speed (Bag/min) | 120-180 | 180-270 | 240-360 |

| Sealing Format | Fin Seal or Envelope Seal | ||

*For powder Auger Filler min. stick pack width is 25 mm.

Application:

Powder, liquid, cream and granule like sugar, coffee packed in a long narrow pouch. Packing for different materials can be accomplished by different dosing unit.