Shrink Packaging Machines

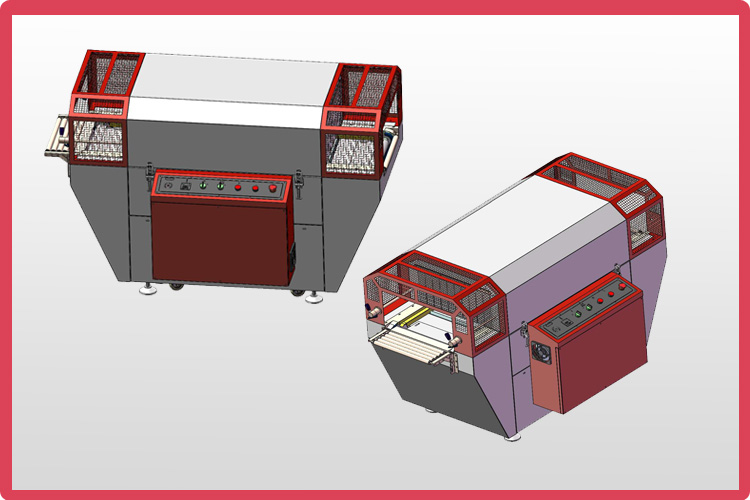

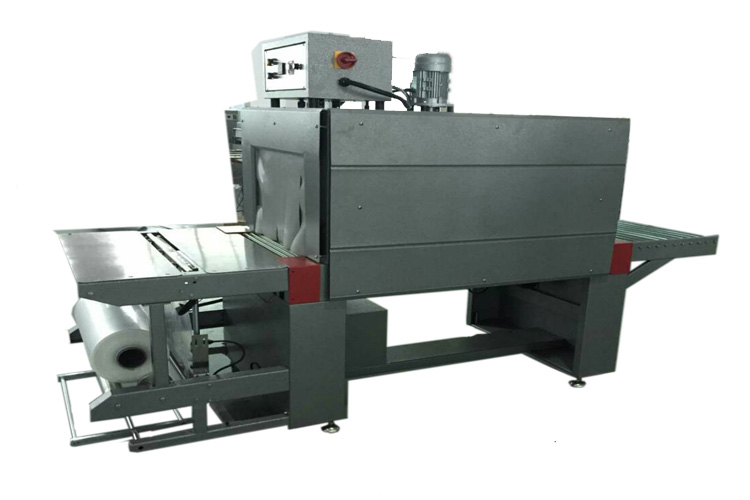

Mini High Performance Heat Shrink Tunnel TLA-1040

Features:

- Thermal circulation system using high integrated design, rapid temperature raise up

- SSR and PID temperature control, temperature tolerance down to +/- 1oC

- Auto shut down function when temperature drops to 70oC, saves time and energy

- Has long life metal heater, durable and stable

- Heater drawer design, for easy inspection and heater connecting and replacement.

- Conveyor speed 1-18M/Min adjustable by VTV speed controller and AC motor

- Standard live roller design

- Air flow from bottom to ensure perfect shrink result

- Insulating layer between the heating zone and outer wall about 100mm to minimize heat lost.

- Tunnel exit with short transfer free roller with angle adjustable.

- Both side lateral air flow direction adjustable.

- With casters

Options:

- Stainless steel machine construction

- Operable tunnel cover

- Different tunnel opening heights available

| Model | TLA-1040 |

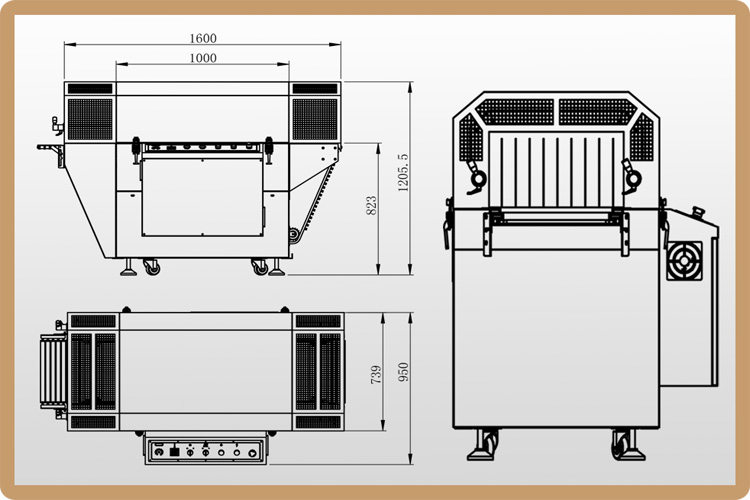

| Tunnel size | L 1000mm x W 400mm x H 250mm |

| Machine size | L 1600mm x W 960mm x H1206mm |

| Conveyor working height | 823mm + 50mm |

| Heater power | 9KW |

| Total power | 10KW |

| Voltage | 380V, 3 phase, 50Hz, 16 A or 220V, 3 phase, 60Hz,26A |

Application

An industrial heat shrink tunnel uses heat to shrink film around packages. TLA-1040 is designed to work with L-bar sealer or sleeve wrapper bundler, but also stands alone for shrink banding applications. Is compatible with a wide range of standard product sizes and offers optimum shrink performance while using minimum space.