Pre-Made Pouch Machines

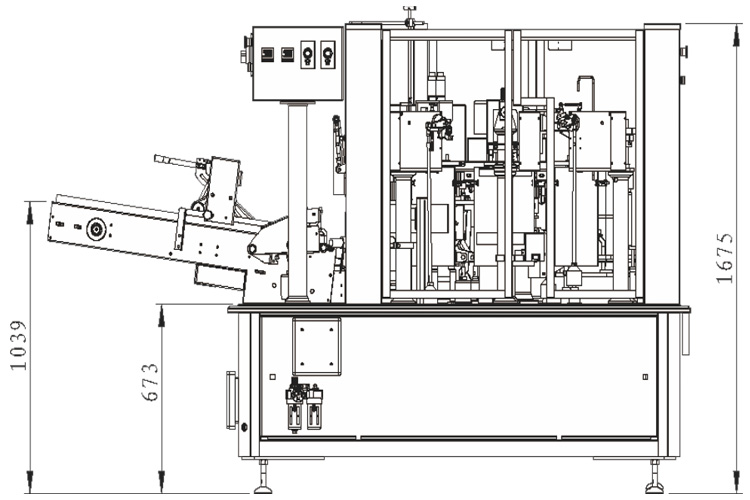

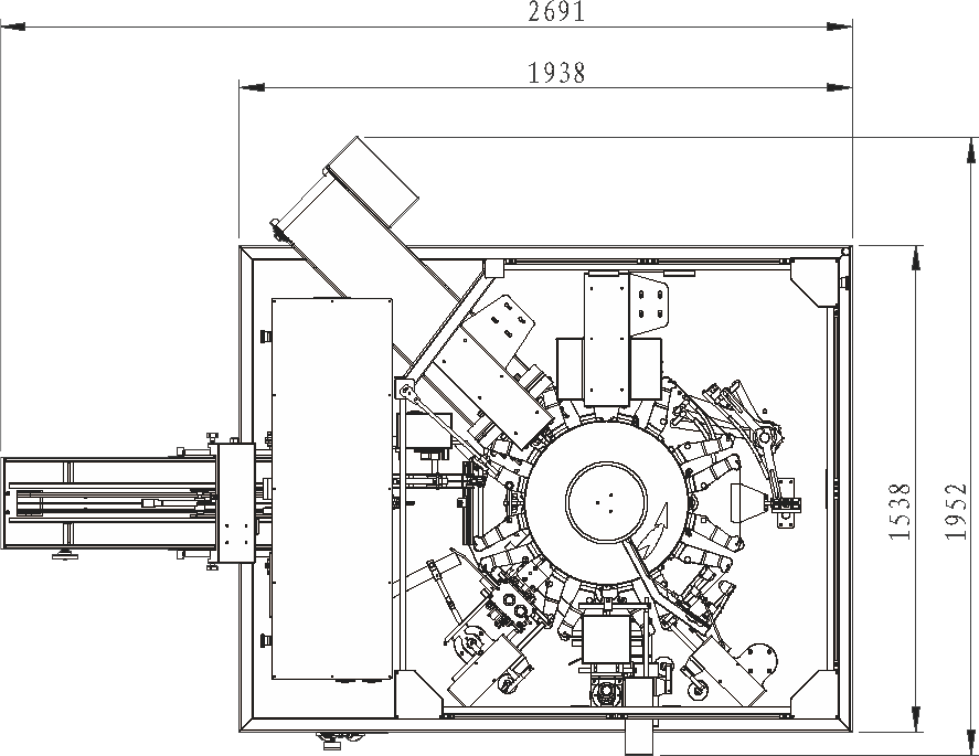

Rotary Filling and Sealing Machine for Premade Pouches AP-8BT/ AP-8BT-XL

Standard Feature:

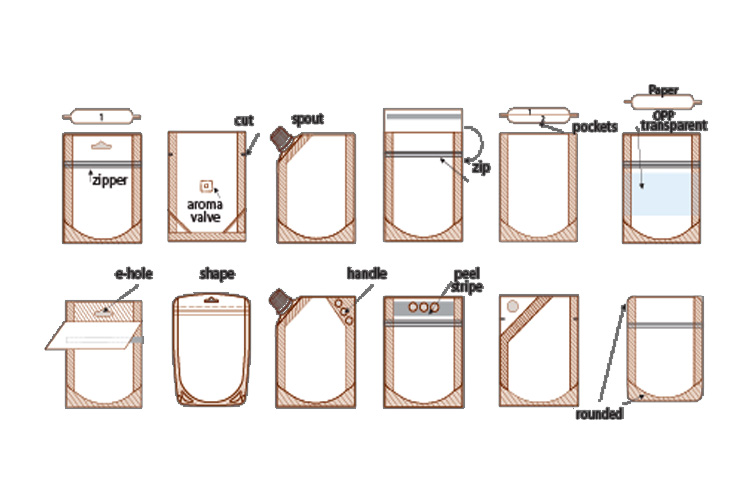

- Intermittent rotary machine with 6 or 8 Stations is designed for handling Pre-made pouches such as Flat and Stand-up Pouches (with/without Zip)

- Operating and adjusting via TOUCH SCREEN.

- Fault indication on the TOUCH SCREEN.

- Hygienic Construction and Easy cleaning.

- High quality and long life of all machine part.

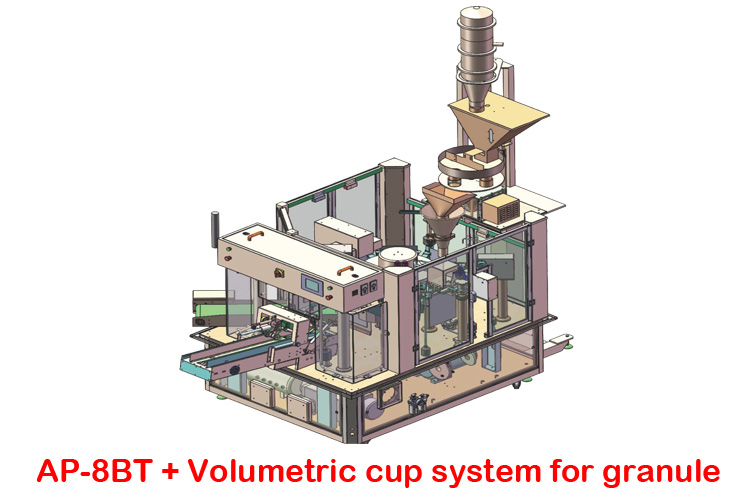

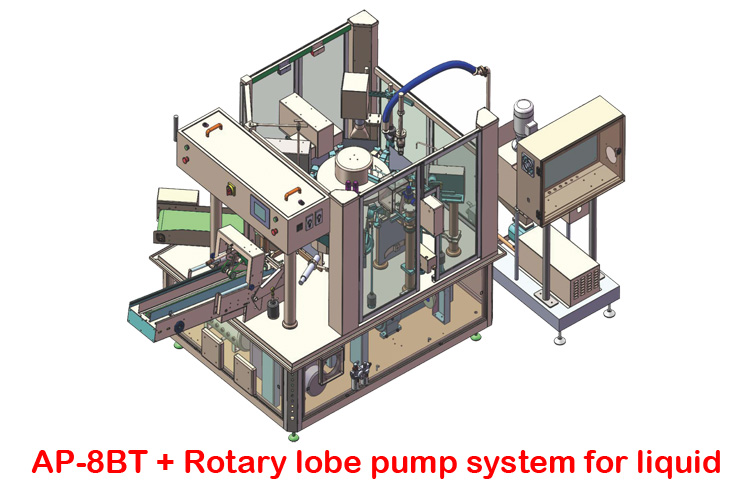

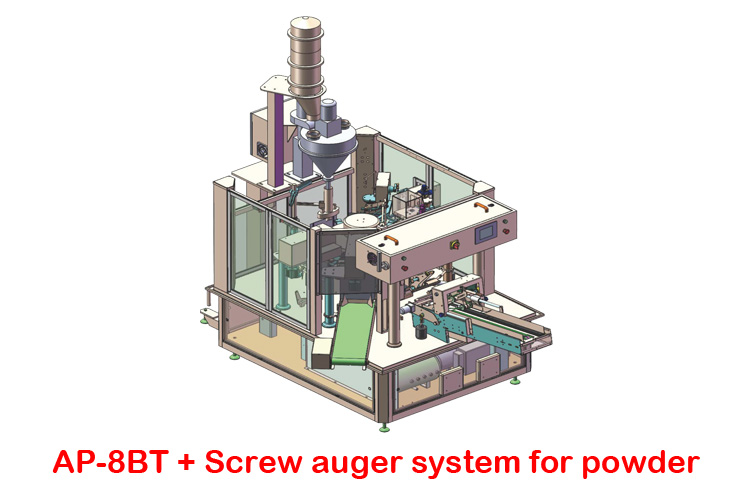

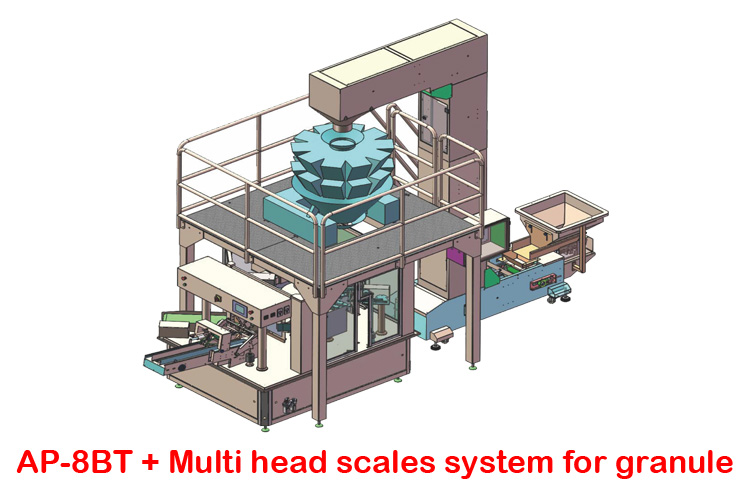

- Integration of various filler, such as Auger filler weighting machine, volumetric doser, Liquid doser, Paste doser and other special doser.

- Simple integration of peripheral equipment.

Safety Device:

- No pouch – No fill – No seal

- Pouch open error – No fill – No seal

- Heater disconnection alarm

- Machine stop at abnormal air pressure

- Machine stop when safety guard is open or electrical cabinet is open

- Safety guard

- Non-open Pouches could be recycled

Packing Process:

- Pouch feeding conveyor & pick up the pouch

- Date coding & Zipper open device (option)

- Open the bottom of pouch, for self-stand pouch

- Pouch top opening

- First filling position

- Second filling position (option)

- First sealing position

- Second sealing position (cold seal) and Pouch feed out conveyor

Standard Equipment:

- Bag Infeed Conveyor

- Bag opening blade with full opening detector

- P.I.D. temperature controller

- Stainless Steel Construction

- Graphical color-touch panel

- Discharge conveyor

Optional Equipment:

- Zipper opening and closing device

- Second filling position

- Safety-guards with safety-switches

- Date coder (Ribbon or Embossing or ink-jet type)

- Deflator

| Model No. | AP-8BT | AP-8BT-XL |

| Max. filling volume(ml) | 2000 | 5000 |

| Bag length (mm) | 150-300 | 200-450 |

| Bag width (mm) | 100-250 | 150-300 |

| Max. Speed (ppm) | 20-45 ppm | 15-35 ppm |

| Pouch format | Flat, Stand-up, Spout, Side gusset pouch, etc… | |

| Pouch feeding | Pouch feeding conveyor | |

Application:

These automatic rotary machines are ideal for a wide variety of pre-made pouch packaging with second filling or cold sealing functions. Couple with different doser, they can full-fill any application with effective and efficiency.

- Powder: Wheat flour, soup –

(By use auger System) - Granule: Sugar, Seasoning –

(By use Volumetric Measure or Scale) - Liquid: Detergent,Shampoo, Rinse, Drinks –

(By piston pump or rotary Pump) - Paste: Retort food-

(By spiral pump or rotary Pump)