Labeling Machines

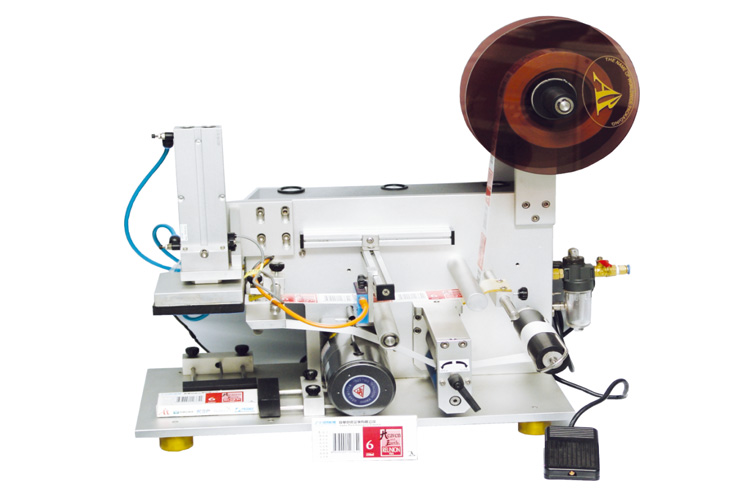

Automatic Label applicator ALB-625 Twin Side Positioning & Wrap-around

Features

- Suitable for labelling on front and back of square containers as well as round bottles.

- Can also apply wrap around labels.

- Can apply labels to a fixed point on the bottles to ensure that the label presentation on every bottle is consistent.

- Stainless Steel #304 use for the main construction of the machine.

- PLC combined with touch screen control system.

- High accuracy labelling, ±1 mm tolerance.

- Servo motor driven labelling head, labelling speed is press belt to ensure high speed and quality labelling.

- Push and Press sponge attachment is used to ensure smooth labelling without wrinkles or bubbles.

- Equipped with bottle separating wheel to keep distance between two bottles.

- Positioning Wrap station for partial wrap-around labelling on round containers.

Optional Extras

- Hot stamp TTO printer.

- Ink jet date printers.

- Transparent label sensor

| Model | ALB-625 |

| Label Height/Width | A: 10-110mm; C: 10-170mm; D: 10-220mm |

| Label Length | 10-250mm |

| Product Dia./Width | A: 30-100 (bigger size is available upon request) |

| Labeling Speed | 12-25m/min |

| Reel Inner/ Outer Dia. | Within 76mm/ 360mm |

| Machine Dimension (mm) | L2750XW1400XH1665 |

Application

This machine is designed for twin side labeling on flat/ oval shape containers and positioning twin side labeling on round bottles.