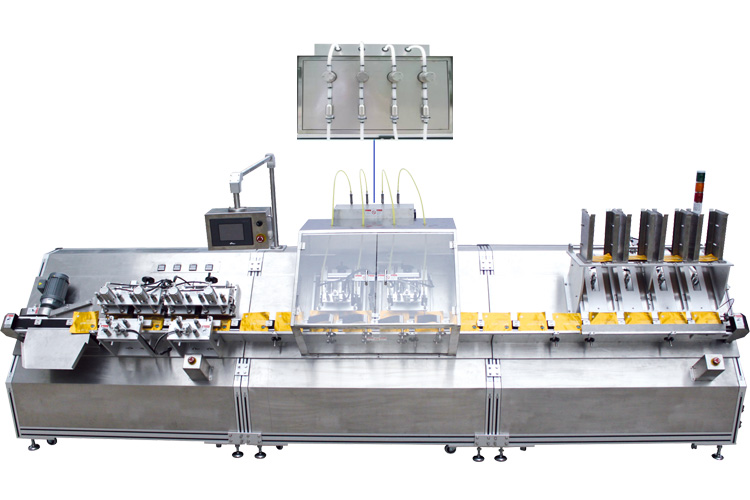

Filling & Capping Machines

Automatic Rotary Level Filling And Capping Machine AP-FL12C6

| 1. | Filling, Cap sorting, Cap Inserting and Capping in one machine, high efficiency and space saving |

| 2. | Gentle gravity fed filling for accurate dosing without foaming. |

| 3. | Quick release change parts |

| 4. | Smooth handling of containers(bottom or neck handling) |

| 5. | Stainless Steel Construction, Low maintenance and down time |

| 6. | High levels of SIP and CIP to ensure optimal level of hygiene, complying to GMP requirements |

| 7. | No Container no fill feature to minimize product wastage |

| 8. | Production friendly operation from base mounted control panel |

| 9. | A safe working environment ensured by full safety guard when confirms to CE standard |

| 10. | Various capping options |

| 11. | Selected electrical parts |

| Option | |

| 1. | Integral CIP system |

| 2. | Container Divert/ Reject System |

| 3. | Nitrogen Dosing System |

| 4. | Vacuum Fill System (for higher viscosity liquid) |

| Model | AP-FL12C6 |

| Filling Capacity | 100 bottles/min. (250ml) |

| Filling Range | 250m -5000ml |

| Height Range | 120-300mm |

| Round Bottle Diameter Range | 45-160mm |

| Applicable Bottle | Square, Rectangular and Oval bottle (To be confirmed upon samples) |

| Applicable Cap Type | Snap Cap, roll-on Cap, Screw Cap |

| Filling Valves No. | 12 |

| Capping Heads No. | 6 |

**(Final speed determined by product viscosity, filling volume, foaming characters as well as bottle and cap design)

Application :

This machine is designed for low viscosity liquid like water, milk, juice filling and capping.