Horizontal Machines

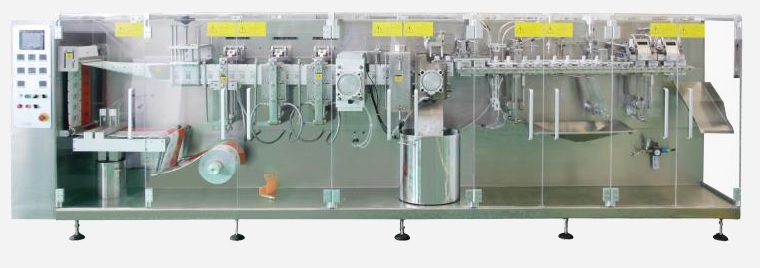

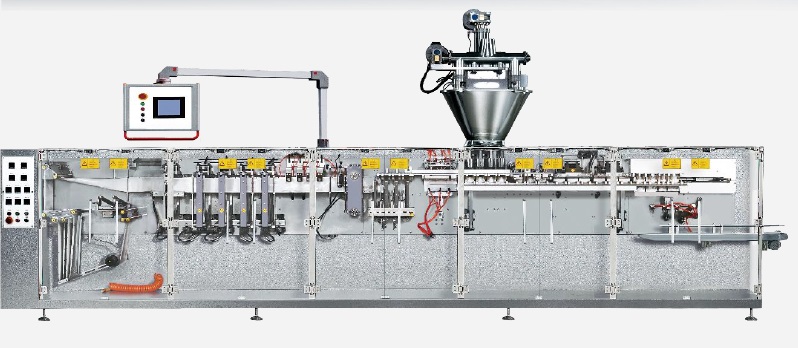

Horizontal Form Fill and Seal Machine

Our APHS series horizontal form, fill and seal machine is specially designed for filling 3 and 4 side sealed sachet and doypack bags. Thanks to the various dosing systems, such as auger dosing, volumetric cup filler and multi-head filler, the machine reliably packs powdered, liquid and granular products (sugar, spices, juice, tomato paste, nuts, sweets, detergents, lotions, pills, capsules, pesticides, fungicides Etc.). The machine also independently produces the bags to be filled from flat film and thus represents a cost-effective and efficient packaging solutionThe modular design of the form, fill and seal machine means that it can be converted and expanded quickly and easily.

| MODEL | APHS-110 | APHS-130 | APHS-180 | APHS-180D | APHS-240 |

| Bag Size | 110x120mm * | 140x180mm | 180x225mm | 90x180mm | 180x225mm |

| Max Bag Volume | 60ml | 160ml | 400ml | 100ml | 1000ml |

| Speed | 40-80 pieces/min** | 40-80 pieces/min | 40-80 pieces/min | 120-180 pieces/min | 30-70 pieces/min |

| Max Connected Load | 2 kw | 3.5kw | 4.5kw | 4.5kw | 5.5kw |

| Machine dimensions (L x W x H) | 2060x750x1400mm | 2850x970x1500mm | 3500x970x1500mm | 3550x970x1500mm | 4600x1120x1500mm |

| machine weight | 600kg | 900kg | 1400kg | 1500kg | 2000kg |

| MODEL | APHS-240D | APHS-270T | APHS-360Q |

| Bag Size | 180x225mm | 90x180mm | 90x180mm |

| Max Bag Volume | 1000ml | 100ml | 100ml |

| Speed | 30-70 pieces/min | 150-240 pieces/min | 200-320 pieces/min |

| Max Connected Load | 5.5kw | 10.5kw | 14 kW |

| Machine dimensions (L x W x H) | 4600x1120x1500mm | 5650x970x1360mm | 7050x970x1360mm |

| machine weight | 2000kg | 2500kg | 3000kg |

* It is not possible to combine all maximum dimensions with each other.

** The output quantity per minute are mean values, depending on film type, thickness, product dimensions and machine handling.

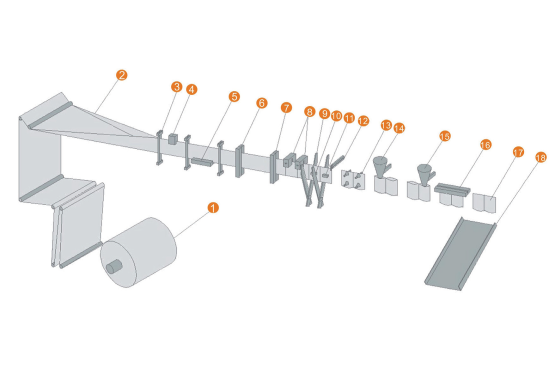

- The film is unrolled (point 1) and the bags are formed (point 2).

- The film is fed in until it reaches the photo sensor (point 4).

- The bottom and sides (points 5 & 6) are sealed.

- The tear score is added (item 7) and the pouch is cut (item 8).

- The pouches are drawn on by the machine and opened (items 9 & 10).

- The pouches are filled and sealed (points 11 & 12).

- The finished product is discharged from the machine (items 13 & 14).

Please contact us for Pricing