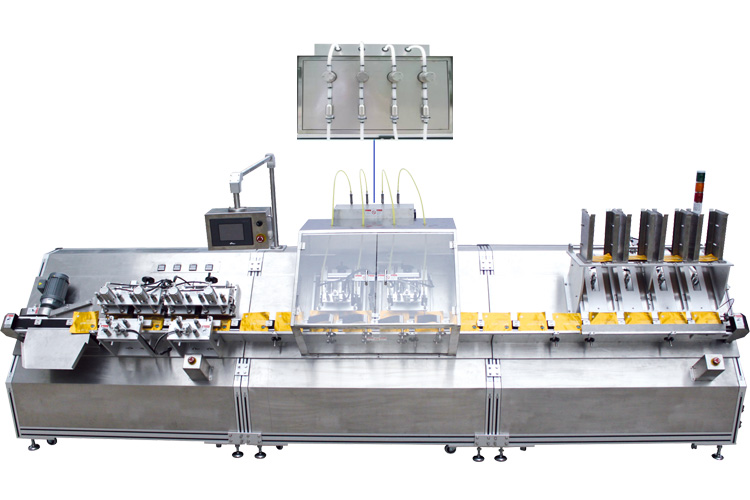

Filling & Capping Machines

Professional Mask Filling & Sealing Machine MFS-04 / MFS-02

Features

- Automatic bag feeding, liquid filling, sealing, printing and bag out feeding.

- All contact parts are made from Stainless Steel #316, complying with GMP requirements.

- Variable filling machines can be chosen for different filling material. Standard is electrical gear pump. Pneumatic piston pump is an option for viscous material filling.

- No bag, no fill, no bag, no seal.

- PLC combined with touch screen control system. Parameters and operation can be done in the panel. Production output and the error message can be easily seen from the screen.

- Digital temperature controllers.

- Selected electric and pneumatic components from reliable international manufactures.

| Model | MFS-04 | MFS-02 |

| Process | Auto. Bag feeding, filling, sealing, printing, unloading | |

| Lane No. | 4 | 2 |

| Capacity | 2200-3000pcs/h | 1200-1500pcs/h |

| Bag Size | W: 90-140mm; L: 100-180mm | |

| Standard Filling Pump | Electrical Gear Pump | |

| Power | 220V/1ph, 3KW | 220V/1ph, 1.5Kw |

| Compress air | 0.6Mpa | 0.6Mpa |

| Machine Size | L5200xW900xH 1700mm | L2600xW900xH1700mm |

Application

This machine is special designed for mask filling and sealing automatically & professionally.