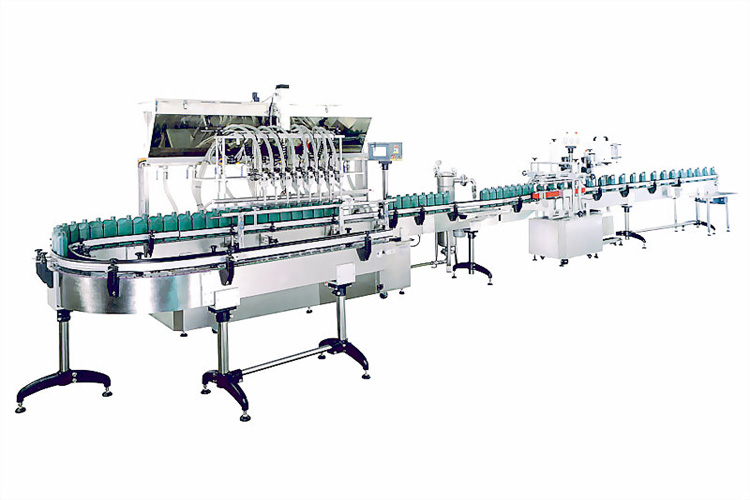

Filling & Capping Machines

Automatic Rotary Lobe Pump Filling Machine AFM-840 / 860 / 880

| 1. | Machine construction in Stain less Stell #304. | |||||||||

| 2. | Each rotary Lobe pump is driven by an individual motor for high accuracy liquid filling. | |||||||||

| 3. | PLC combined with touch screen contol system. Filling volume can be easily adjusted separately. | |||||||||

| 4. | No change parts are required for different bottle sizes. | |||||||||

| 5. | Diving type filling system prevents spillage during filling. | |||||||||

| 6. | No bottle, no filling safety device. | |||||||||

| 7. | 20 job memory for easy recall. | |||||||||

| 8. | You can choose A type, B type or C type for different filling range. | |||||||||

| Option | ||||||||||

| 1. | Liquid Tank Agitator | |||||||||

| 2. | Hot Filling | |||||||||

| 3. | Infeed and outfeed turn table | |||||||||

| 4. | All contact parts made of Stainless Steel #316. | |||||||||

| 5. | Safety Transparent cover for safe operation circumstance and dust-proof. | |||||||||

| Model | AFM-840 | AFM-860 | AFM-880 |

| Filling Range | A: 30-500ml; B: 100-1000ml; C:500-5000ml | ||

| Power | 200V/1ph, 500/60Hz. | ||

| Filling Pump | Stainless Steen Rotary Lobe Pump | ||

| Max. Filling Capacity | 24 bottles/min | 36 bottles/min | 48 bottles/min |

| Filling Nozzle No. | 4 | 6 | 8 |

This machine is designed for handle from water-thin to high viscosity product, especially for viscid and foaming product in chemical, food, beverage, pharmaceutical, and biotechnology industry.