Table Top Pneumatic Type Sealing Machine

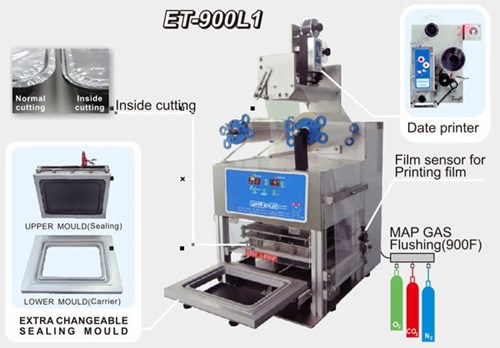

Table Type Air Motive Sealing Machine-ET-900

Features

1. Stainless steel frame and anodized alloy.2. Low-maintenance, compact design.

3. Digital controller panel with microcomputer program for different setting.

4. Microcomputer with multi-function design and error code detection.

5. Front safety guard for emergency.

6. Operation can be set as manual or automatic (Photo-sensor).

7. Three models for film feeding: Sensor, encoder, timer.

8. Available for colourful & blank film.

9. Quick interchangeable mould / tooling.

Specification

| Model | Power | Weight(kg) | Capacity(psc/hr) | Max.Cup Size(mm) | Machine Size(mm) WxDxL |

| ET-900S1 | 110/220V | 60 | 450 | 220x170x120 | 350x500x820 |

| ET-900S2 | 110/220V | 65 | 800 | 100x170x120 | 350x500x820 |

| ET-900S4 | 110/220V | 70 | 1350 | 100x75x120 | 350x500x820 |

| ET-900L1 | 110/220V | 70 | 420 | 320x250x120 | 480x705x820 |

| ET-900L2 | 110/220V | 75 | 750 | 150x250x120 | 480x705x820 |

| ET-900L4 | 110/220V | 80 | 1250 | 150x110x120 | 480x705x820 |

| ET-900XL1 | 110/220V | 85 | 390 | 350x260x120 | 510x760x820 |

| ET-900XL2 | 110/220V | 90 | 700 | 160x280x120 | 510x760x820 |

| ET-900XL4 | 110/220V | 95 | 1150 | 160x120x120 | 510x760x820 |

| ET-900XXL1 | 110/220V | 115 | 360 | 420x290x120 | 580x865x820 |

| ET-900XXL2 | 110/220V | 120 | 650 | 195x290x120 | 580x865x820 |

| ET-900XXL4 | 110/220V | 125 | 1050 | 195x130x120 | 580x865x820 |

Application

1. For round cup sealing : Water, juice, jelly, pudding...2. For square tray sealing : Lunch box, Tofu, fresh frozen food, seafood, agricultural processed product...

3. Or any others: Cosmetics and pharmaceutical product. Many kinds of packaging product by plastic or paper container.

Optional Function

1. Date Printer / Coder (Hot ink manual, Times Roman 12 font, 5 rows x 9 alphanumeric lines).2. Holder and Pole Supporter for bottle design.

3. MAP (GAS flushing): Modified atmosphere packaging.

4. Inside cutting.